University will conduct examination for 100 marks for this subject

Contact Hours/week: Lectures -2 ; Practicles -4

Syllabus

1. Introduction to Engineering Graphics: Drawing instruments and accessories, BIS - SP 46. Use of plane scales and Representative Fraction.

2. Engineering Curves: Classification of Engineering Curves, Construction of Conics, Cycloidal Curves, Involutes and Spirals.

3. Loci of Points: Path of the points moving on simple arrangements and simple mechanisms, slider crank mechanism, four bar chain mechanism etc.

4. Projections of Points & Lines: Introduction to principal planes of projections, Projections of the points located in same quadrant and different quadrants, Projections of line with its inclination to one reference plane and with two reference planes. True length of the line and its inclination with the reference planes.

5. Projections of Planes: Concept of different planes, Projections of planes with its inclination to one reference plane and with two reference planes. Concept of auxiliary plane method for projections of the plane.

6. Projections of Solids & Section of Solids: Classification of solids. Projections of solids like Cylinder, Cone, Pyramid and Prism with its inclination to one reference plane and with two reference planes. Section of such solids and the true shape of the section.

7. Development of Lateral Surfaces: Concept of development of the different surfaces. Parallel Line Development and Radial Line Development.

8. Orthographic Projections: Principle of projection, Principal planes of projection, Projections from the pictorial view of the object on the principal planes for View from Front, View from Top and View from Side using first angle projection method and third angle projection method, Full Sectional View.

9. Isometric Projections and Isometric View or Drawing: Isometric Scale, Conversion of orthographic views into isometric projection, isometric view or drawing.

NOTE: Topic No. 1, 8 and 9 of the above syllabus to be covered in Practical Hours.

Text Books:

1. Engineering Drawing By Agrawal and Agrawal, Tata McGraw Hill, New Delhi.

Reference Books:

1. A Text Book of Engineering Graphics By P.J.Shah, S.Chand & Company Ltd., New Delhi

2. A Text Book of Machine Drawing By P.J.Shah, S.Chand & Company Ltd., New Delhi

3. Elementary Engineering Drawing By N.D.Bhatt, Charotar Publishing House, Anand

4. Geometrical and Machine Drawing By N.D.Bhatt, Charotar Publishing House, Anand

5. Engineering Graphics – I and II By Arunoday Kumar, Tech – Max Publication, Pune

6. Engineering Drawing & Graphics using Auto CAD 2000 By T. Jeyapoovan, Vikas Publishing House Pvt. Ltd., New Delhi

7. A text book of Engineering Drawing By R.K.Dhawan, S.Chand & Company Ltd., New Delhi

8. A text book of Engineering Drawing By P.S.Gill, S.K.Kataria & sons, Delhi

9. Engineering Drawing with an Introduction to AutoCAD By D.A.Jolhe, Tata McGraw-Hill Publishing Co. Ltd., New Delhi

10. Computer Aided Engineering Drawing, S. Trymbaka Murthy, I.K.International Publishing House Pvt. Ltd., New Delhi

Thursday, November 25, 2010

Saturday, November 20, 2010

Syllabus of JNTU Bachelor of Technology (BTech Common Syllabus) - CM05219 Engineering Chemistry / CM05044 Applied Chemistry Effective 2007-08 Batch

UNIT I: Water Technology-I

Introduction, Effect of Water on Rocks and Minerals, Types of impurities in Water, Hardness of Water - Temporary and Permanent hardness. Units and inter conversions of Units. Estimation of hardness by EDTA Methods. Problems on Temporary and Permanent hardnesses. Analysis of Water - Alkalinity; Chlorides and Dissolved Oxygen. Disadvantages of Hard Water. Methods of Treatment of Water for Domestic Purposes - Sedimentation, Coagulation, Filtration, Disinfection - Sterilization, Chlorination,Break point chlorination, Ozonization.UNIT II: Water Technology-II

Water for Industrial purpose - Water for Steam Making-Boiler Troubles - Carry Over - Priming and Foaming, Boiler Corrosion, Scales and Sludges, Caustic Embrittlement. Water Treatment: - Internal Treatment - Colloidal, Phosphate, Calgon, Carbonate, Sodium aluminate Conditioning of Water. External Treatment - Lime-Soda Process, Zeolite Process, Ion- Exchange Process; - Numerical Problems.UNIT III: Science of Corrosion

Definition, Examples, Types of Corrosion: Theories of Corrosion and Mechanism - Dry Corrosion, (Direct Chemical attack), Wet Corrosion, (Electro Chemical Theory) Principles of Corrosion, Galvanic Series, Galvanic Corrosion, Concentration Cell Corrosion, Mechanism of Wet Corrosion - Hydrogen evolution type, Oxygen absorption type. Factors Influencing Corrosion. Control of Corrosion - Proper Design, Use of pure metal and metal alloys, Passivity, Cathodic Protection - Sacrificial anode and Impressed Current. Modifying the Environment, use of Inhibitors.UNIT IV: Protective Coatings and their applications

Surface Preparation: (1) Solvent Cleaning (2) Alkali Cleaning (3) Pickling and Etching (4) Sand Blasting (5) Mechanical Cleaning.Types of Protective Coatings: Metallic Coatings - Anodic Coatings, Galvanization, Cathodic Coatings - Tinning, Metal Cladding, Electroplating Ex: Chromium Plating, Metal Spraying, Cementation-Sheradizing, Colourizing, Chromizing.

Chemical Conversion Coatings: (1) Phosphate (2) Chromate (3) Anodized Coatings.

UNIT V: Polymer Science and Technology

Polymerization Reactions - Basic concepts. Types of Polymerization - Addition and Condensation Polymerizations. Plastics -Thermosetting and Thermoplastics - Differences. Compounding and Moulding of Plastics - Compression, Injection, Transfer, and Extrusion molding methods. Preparation, Properties and Engineering Uses of the Following: Polyethylene, PVC, Teflon, Bakelite, Nylon, Polyester, Polyurethane and Silicone Resins. Rubber - Processing of Natural Rubber, Vulcanization and Compounding. Elastomers - Buna S, Buna N, Thiokol. Polyurethane Rubber.UNIT VI: Refractories and Insulators

Refractories - Definition, Classification With Examples; Criteria of a Good Refractory Material; Causes for the failure of a Refractory Material; Insulators - Definition and Classification with Examples; Characteristics of Insulating Materials; Thermal Insulators, Electrical Insulators - Their Characteristics and Engineering Applications.UNIT VII: Lubricants

Principles and function of lubricants - Types of Lubrication and Mechanism - Thick Film or Hydrodynamic Lubrication, Thin Film or Boundary Lubrication, Extreme Pressure Lubrication. Classification and properties of lubricants-Viscosity, flash and fire point, cloud and pour point, aniline point, Neutralization Number and mechanical strength.UNIT VIII: Inorganic Cementing Materials

Cement: Important Parameters for Manufacturing Cement Clinkers. Chemical Constituents and Composition of Cement. Methods of Manufacture of Cement - Wet and Dry Processes. Additives for Cement. Properties of Cement - Setting and Hardening. Types of Portland Cement.TEXT BOOKS

1. A text book of Engineering Chemistry by Jain & Jain, Dhanpat Rai Publishing Company, New Delhi(15 Ediction) (2006).2. Chemistry of Engineering Materials by C.P. Murthy, C.V. Agarwal and A. Naidu BS Publication Hyd. 2007.

REFERENCE

1. A text book of Engineering Chemistry by S.S. Dara, S.Chand & Co, New Delhi (2004)2. Engineering Chemistry by J C Kuriacose and J. Rajaram, Tata McGraw-Hill Co, New Delhi (2004)

3. Text book of Engineering Chemistry by Shashi Chawala, Dhanpat Rai Publishing Company, 15th edition New Delhi (2004).

4. Laboratory Manual on Engineering Chemistry by S.K. Bhasin and Sudha Rani, Dhanpat Rai Publishing Company, New Delhi (2004).

5. Engineering Chemistry by R. Gopalan, D. Venkappaya and S.Nagarajan, Vikas Publishing House, New Delhi (2004).

6. Engineering Chemistry by R.V. Gadag A.N. Tyanand Shortly IK. International Publishing house Pvt. Ltd. New Delhi.

Additional books for Mechanical Engineer

ing (Production)

Syllabus of JNTU Bachelor of Technology (BTech Common Syllabus) - PY05227 Engineering Physics and Applied Chemistry Lab Effective 2007-08 Batch

Any ten of the following experiments are to be performed during the Academic year.

Sl. No. - Name of the Experiment

1. Determination of Refractive Index of the material of a Prism - Spectrometer.

2. Dispersive power of the material of a Prism - Spectrometer.

3. Cauchy's constants - Spectrometer.

4. Determination of wavelength of a source - Diffraction Grating.

5. Determination of thickness of a thin object using parallel fringes.

6. Newton's Rings.

7. Determination of Rigidity modulus of a material in the form of a wire - Torsional pendulum

8. Melde's Experiment - Transverse and Longitudinal modes.

9. Determination of velocity of sound - Volume resonator.

10. Single slit diffraction using Sodium lamp.

11. Double slit diffraction using Sodium lamp.

12. Single slit diffraction using Lasers.

13. Double slit diffraction using Lasers.

14. Time constant of R-C Circuit.

15. L-C-R Circuit.

16. Verification of laws of stretched string - Sonometer.

17. Calculation of Frequency of A.C. mains - Sonometer.

18. Study of Characteristics of LED and LASER sources.

19. Study of Characteristics of p-i-n and avalanche photo diode detectors.

20. Bending losses of fibers.

21. Evaluation of Numerical Aperture of a given fiber.

22. Magnetic field along the axis of a current carrying coil - Stewart and Gee's method.

23. Hall effect.

24. B-H curve.

25. Energy gap of a material of p-n junction.

26. Determination of Young's modulus and Poisson's ratio by Cornu's method

27. Thermo Electric effect - Seebeck effect and Peltier effect.

2. Preparation of Standard Potassium Dichromate and Estimation of Ferric Iron.

5. Preparation of Standard EDTA and Estimation of Copper

8. Percentage Purity of Lime Stone.

10. Iron in Cement

2. Vogel's Book of Quantitative Inorganic Analysis, ELBS Edition.

Sl. No. - Name of the Experiment

1. Determination of Refractive Index of the material of a Prism - Spectrometer.

2. Dispersive power of the material of a Prism - Spectrometer.

3. Cauchy's constants - Spectrometer.

4. Determination of wavelength of a source - Diffraction Grating.

5. Determination of thickness of a thin object using parallel fringes.

6. Newton's Rings.

7. Determination of Rigidity modulus of a material in the form of a wire - Torsional pendulum

8. Melde's Experiment - Transverse and Longitudinal modes.

9. Determination of velocity of sound - Volume resonator.

10. Single slit diffraction using Sodium lamp.

11. Double slit diffraction using Sodium lamp.

12. Single slit diffraction using Lasers.

13. Double slit diffraction using Lasers.

14. Time constant of R-C Circuit.

15. L-C-R Circuit.

16. Verification of laws of stretched string - Sonometer.

17. Calculation of Frequency of A.C. mains - Sonometer.

18. Study of Characteristics of LED and LASER sources.

19. Study of Characteristics of p-i-n and avalanche photo diode detectors.

20. Bending losses of fibers.

21. Evaluation of Numerical Aperture of a given fiber.

22. Magnetic field along the axis of a current carrying coil - Stewart and Gee's method.

23. Hall effect.

24. B-H curve.

25. Energy gap of a material of p-n junction.

26. Determination of Young's modulus and Poisson's ratio by Cornu's method

27. Thermo Electric effect - Seebeck effect and Peltier effect.

REDOX TITRATIONS

1. Preparation of Standard Potassium Dichromate and Estimation of Ferrous Iron.2. Preparation of Standard Potassium Dichromate and Estimation of Ferric Iron.

IODOMETRY

3. Preparation of Standard Potassium Dichromate and Estimation of Copper, by Iodometry.COMPLEXOMETRY

4. Preparation of Standard EDTA solution and Estimation of Calcium/Hardness of Water.5. Preparation of Standard EDTA and Estimation of Copper

PRECIPITATION TITRATION

6. Preparation of Standard solution of Zinc and Estimation of Ferrocyanide.ANALYSIS OF MINERALS

7. Percentage Purity of Pyrolusite.8. Percentage Purity of Lime Stone.

COLORIMETRIC ESTIMATIONS

9. Manganese in Steel10. Iron in Cement

TEXT BOOKS

1. Chemistry Pre-lab manual by Dr K.N.Jayaveera and K.B. Chandra Sekhar, S.M. Enterprizes Ltd.2. Vogel's Book of Quantitative Inorganic Analysis, ELBS Edition.

Engineering Drawing Practice Lab (As per JNTU Syllabus) Book Description

This textbook, Engineering Drawing Practice Lab is specifically designed as per the syllabus of the first year students of the circuit branches in various engineering colleges affiliated to Jawaharlal Nehru Technological University (JNTU), Andhra Pradesh. Both the text and drawings presented represent latest concepts.

The book is illustrated with numerous solved problems from various leading universities so as to expose our students to all sorts of questions put to them in their examinations. The topics include bolt and nut, L-angle, funnel, table, stool, overhead tank, gland, stage, cavity block, drilling jig, cast iron and steel castings, hopper, chimney, duct, chute, V-block, bearing cap, open bearing, dovetail, fork, rocker arm, lock plate, trisquare, jig plate, flange, elbow, shaft bracket, machine clamp, tailstock, angle plate, electromagnet, I-beam, rod support, tray etc.

In view of the treatment of this subject reasonably in detail and the book being written in a simple language within the comprehension of an average student, it should serve as an ideal textbook not only for the students of JNTU but all others pursuing this subject in various universities, both in India and other developing countries.

About the Author(s):

Prof. K. Venugopal , B.E., M.Sc. (Engg.), F.I.E., M.I.S.E., M.I.S.T.E., is a retired Professor of Mechanical Engineering, Government College of Technology, Coimbatore. He obtained his UG and PG degrees from the University of Madras. He served as a Design Engineer in a reputed firm at Mumbai. Subsequently, he had been on the Faculty of Mechanical Engineering in the Department of Technical Education, Tamil Nadu for over a period of 35 years.

He is a recipient of `The Best Citizen of India` award from an International Publishing House, in New Delhi. He is a Fellow of the Institution of Standards Engineers of the Bureau of Indian Standards (B.I.S.), Member of the Institution of Engineers and Life Member of Indian Society for Technical Education.

Contents:

Importance of Engineering Graphics Drawing Instruments and Their Uses

BIS Conventions and Specifications

Engineering Scales

Geometrical Constructions

Curves Used in Engineering Practice-Conic Sections

Cycloids and Involutes

Cylindrical Curves

Freehand Sketching Techniques

Orthographic Projections

Representation of 3-D Objects

Projections of Points

Projections of Straight Lines

Projections on Auxiliary Planes

Projections of Plane Surfaces

Projections of Solids

Auxiliary Projections of Solids

Isometric Projection

Conversion of Orthographic Views into Isometric Views

Conversion of Isometric Views into Orthographic Views.

The book is illustrated with numerous solved problems from various leading universities so as to expose our students to all sorts of questions put to them in their examinations. The topics include bolt and nut, L-angle, funnel, table, stool, overhead tank, gland, stage, cavity block, drilling jig, cast iron and steel castings, hopper, chimney, duct, chute, V-block, bearing cap, open bearing, dovetail, fork, rocker arm, lock plate, trisquare, jig plate, flange, elbow, shaft bracket, machine clamp, tailstock, angle plate, electromagnet, I-beam, rod support, tray etc.

In view of the treatment of this subject reasonably in detail and the book being written in a simple language within the comprehension of an average student, it should serve as an ideal textbook not only for the students of JNTU but all others pursuing this subject in various universities, both in India and other developing countries.

About the Author(s):

Prof. K. Venugopal , B.E., M.Sc. (Engg.), F.I.E., M.I.S.E., M.I.S.T.E., is a retired Professor of Mechanical Engineering, Government College of Technology, Coimbatore. He obtained his UG and PG degrees from the University of Madras. He served as a Design Engineer in a reputed firm at Mumbai. Subsequently, he had been on the Faculty of Mechanical Engineering in the Department of Technical Education, Tamil Nadu for over a period of 35 years.

He is a recipient of `The Best Citizen of India` award from an International Publishing House, in New Delhi. He is a Fellow of the Institution of Standards Engineers of the Bureau of Indian Standards (B.I.S.), Member of the Institution of Engineers and Life Member of Indian Society for Technical Education.

Contents:

Importance of Engineering Graphics Drawing Instruments and Their Uses

BIS Conventions and Specifications

Engineering Scales

Geometrical Constructions

Curves Used in Engineering Practice-Conic Sections

Cycloids and Involutes

Cylindrical Curves

Freehand Sketching Techniques

Orthographic Projections

Representation of 3-D Objects

Projections of Points

Projections of Straight Lines

Projections on Auxiliary Planes

Projections of Plane Surfaces

Projections of Solids

Auxiliary Projections of Solids

Isometric Projection

Conversion of Orthographic Views into Isometric Views

Conversion of Isometric Views into Orthographic Views.

Book Details

| Title: | Engineering Drawing Practice Lab (As per JNTU Syllabus) |

| Publisher: | New Age International |

| Author: | K Venugopal |

Saturday, November 13, 2010

digital systems

As the complexity of modern digital systems increases, so does the need for ever more rigorous testing at all levels, from individual chips up to complete system architectures. This book is the most comprehensive introduction available to the range of techniques and tools used in digital testing. It covers every key topic, including fault simulation, CMOS testing, design for testability, and built-in self test. Aimed at graduate students of electrical and computer engineering, the book is also the most up-to-date reference on the market for practicing engineers

Friday, November 12, 2010

satilite communication

The first satellite that was used for communication purpose in INDIA was ARYABHATTA and it was launched in 19th April.1975. It was made and assembled by an organization called Indian Space Research Organization (ISRO). In the year 1981, a satellite named APPLE was launched in space which was the first Indian Experimental communication satellite. The unique feature of it was that it was a three axis stabilization geosynchronous satellite and weighed around 645 kg. The term APPLE is an abbreviation for Ariane Passenger Payload Experiment. It consisted of a (6/4 Ghz) processing equipment called Transponder. Various experiments were carried out with APPLE, [SITE, STEP (Other satellite telecommunication experiment projects)] and the results obtained from these experiments provided an impetus for Govt. of India to have its own multipurpose Geosynchronous Earth Orbit satellite under INSAT (Indian National Satellite) program. The first satellite INSAT-1A was launched in the year 1982 which was under this INSAT program, but this effort went in vain as the power house of this satellite consisting of solar cells did not operate properly( failed to open) and this satellite was unused latter on. The average electrical power required by INSAT-1 was approximately 1000W and was provided by the power house subsystem of the satellite. The payload was one C-band transponder and two S-band transponders. Later succession of INSAT-1 series was launched like INSAT-1B, INSAT-C and INSAT-D. After this due to the success of the first generation satellites, INSAT-2 series was launched viz. INSAT-2A, INSAT-2B, INSAT-2C, INSAT-3D and INSAT-2E which provided variety of services.

WHAT IS SATELLITE?

A Satellite is a solid object which revolves around some heavenly body due to the effect of gravitational forces which are mutual in nature. We can categorize satellites in two types, namely Passive Satellites and Active satellites. Passive satellites are not like active satellites. Even a moon can be a passive satellite. Thus passive satellites are relay stations in space. A passive satellite can be further subdivided into two types, namely Natural satellites and artificial satellites. A moon is a natural satellite of earth. But spherical balloon with metal coated plastic serve as artificial satellites.

Active satellites are complicated structures having a processing equipment called Transponder which is very vital for functioning of the satellite. These transponders serve dual purpose i.e. provides amplification of the incoming signal and performs the frequency translation of the incoming signal to avoid interference between the two signals.

All ABOUT SATELLITE COMMUNICATION

The term Satellite communication is very frequently used, but what is satellite communication? It is simply the communication of the satellite in space with large number of earth stations on the ground. Users are the ones who generate baseband signals, which is processed at the earth station and then transmitted to the satellite through dish antennas. Now the user is connected to the earth station via some telephone switch or some dedicated link. The satellite receives the uplink frequency and the transponder present inside the satellite does the processing function and frequency down conversion in order to transmit the downlink signal at different frequency. The earth station then receives the signal from the satellite through parabolic dish antenna and processes it to get back the baseband signal. This baseband signal is then transmitted to the respective user via dedicated link or other terrestrial system. Previously satellite communication system used large sized parabolic antennas with diameters around 30 meters because of the very faint and weak signals received. But nowadays satellites have become much stronger, bigger and powerful due to which antennas used have become automatically smaller in size. Thus the earth station antennas are now not large in size as the antennas used in olden days. A satellite communication system operates and works in the millimeter and microwave wave frequency bands from 1 Ghz to 50 Ghz. There are various frequency bands utilized by satellites but the most recognized of them is the uplink frequency of 6 Ghz and the downlink frequency of 4 Ghz. Actually the uplink frequency band is 5.725 to 7.075 Ghz and the actual downlink frequency band is from 3.4 to 4.8 Ghz. The major components of a Satellite Communication system is spacecraft and one or more earth earths.

THE EXCITING COMPONENTS OF SATELLITE i.e ITS SUBSYSTEMS

- Attitude & orbit control system:

This subsystem comprises of rocket motors that keeps the correct orientation of the satellite in space by moving it back to the correct orbit. Various external forces cause to change the parking position of the satellite. The primary factors are gravitational forces of sun, moon earth and also other planets of solar system. Other factors include solar pressure on the antennas and solar sails, which is present on the body of the satellite. All these factors are hugely responsible for misbalancing of the satellite and also responsible for changing the parking position of the satellite. Apart from this the earth’s magnetic field is also playing a major role in changing the parking position of satellite. The earth’s magnetic field generates eddy currents in the metallic structure of the satellite as the satellite moves through the magnetic field. Thus the body of the satellite gets rotated called as wobble of the satellite.

Remedy for Misbalancing of the satellite: station keeping: It is a method of periodically accelerating the satellite in the opposite direction against the forces acting on the body of the satellite like gravitational forces, eddy currents etc. in order to maintain the correct orientation of satellite in space and maintaining its orbit. The two most common methods employed to keep the satellite stable in orbit are: spin stabilization and three axes body stabilization.

- TTC and M SUBSYSTEMS:

These subsystems are found partly on the satellite and partly on the earth stations. Data obtained from the sensors present on the spacecraft are sent by the Telemetry systems through telemetry link to the controlling earth stations. The telemetry system monitors the condition of the spacecraft. Furthermore the Tracking system is present on the earth station which is all concerned about range, azimuth angles and elevation angles of the spacecraft by providing necessary information on it. There are various techniques used for tracking of satellite:

- Velocity and acceleration sensors on the satellite can be used to establish the change in orbit.

- Doppler shift of the telemetry carrier from the earth station or beacon transmitter may be measured to determine the rate at which the range is changing.

- Ranging tones may be used for range measurement.

- POWER SUBSYSTEM:

This is required to run satellite’s housekeeping and communication system. The block diagram of the power subsystem is shown as:

Solar panels generate direct current which is used to operate different subsystems. The batteries like Nickel-Cadmium batteries are charged by the DC power by employing the battery chargers. The stabilized low voltage is supplied to power various subsystems which are generated by the voltage regulator circuits. A dc to dc converter circuit generates high voltage dc which is used for operating the traveling wave tube amplifiers. Generation of ac from dc is done by dc to ac inverter circuits for running ac devices.

- PROPULSION SUBSYSTEM

This subsystem can also be called as a reaction control subsystem. It is carried by the satellite in the GEO orbit. The dominant functions of it are:

· It helps the spacecraft to move to its assigned position in orbit and also helps to maintain it in that position.

· It is also used to maintain the direction of spin axis attitude control against the perturbation forces.

The main components of propulsion subsystem are: Low thrust actuators, High thrust motors eg: apogee kick motor, Apogee boost motor and finally Perigee kick motor. Low thrust actuators are further classified as Chemical thrusters and Electrical thrusters. These thrusters are used for attitude and orbit corrections. Moreover the Electric thrusters are mainly of two types 1.> Plasma thrusters 2.> Ion thrusters.

- SPACECRAFT ANTENNA (subsystem)

Antenna subsystem is also an essential component of satellite system. Basically four main type of antennas are used: these are Monopoles and dipoles (wire antennas) which are mainly used in VERY HIGH FREQUENCY AND ULTRA HIGH FREQUENCY to provide communication for TTC and M subsystem. 2.> Horn antennas are mainly used at microwave frequencies. Horns are actually used as feeds for reflector. 3.> Array antennas are actually phased array antennas which are used on satellites to form multiple beams from single aperture. 4> Reflector antennas are commonly used for earth station antennas and the most widely employed shape of it is the paraboloid with a feed placed at its focus. The patterns for different satellite antennas are shown as:

- THE KEY ELECTRONIC EQUIPMENT IN A SATELLITE OR TRANSPONDERS:

It is the key electronic component in a satellite. The transmitter receiver combination in a satellite is known as a Transponder. It performs two major functions 1.> It provides amplification of the signal thus providing a gain of around 110dB. 2> It also does the frequency down conversion or frequency translation of the uplink signal in order to avoid interference between the received and the transmitted signal.

Types of Transponders: 1. Bend pipe type Transponder 2. Regenerative type Transponder.

Bend pipe type transponders are also called conventional type transponders.

Diplexer (acting as a two-way microwave gate) is the device which is responsible or used by the satellite for both receiving the uplink signal and transmitting the downlink signal. The frequency down conversion is done in the carrier processor. Amplification of the weak received signal is done in the front end. The downlink frequency is brought to a sufficient power level by amplification by the power amplifier such as Traveling Wave tube. The carrier processing equipment determines whether the transponder is of conventional or regenerative type

Regenerative Transponders: The regenerative transponder is one where there is provision for detection and demodulation process. The main advantages for these kind of transponders are:

· The signal to noise ratio is improved.

· These are simpler and more flexible to implement.

· At low baseband frequency the amplification is easier to obtain in case of regenerative type.

Types of multi channel transponder systems:

- Broadband system

- Dual channelized system.

The various frequency translation schemes in use:

FOR CONVENTIONAL TRANSPONDERS

- RF-RF Translation: This is a single mixer system. The diagrams of it is shown below:

- RF-IF-RF translation schemes: This is a double conversion scheme using a single stable oscillator. This kind of translation scheme provides two advantages over RF-RF conversion scheme: 1. The process of carrier filtering is done at the IF band. 2. Before the return transmitted signal the uplink carriers can be easily removed. The diagram of it is shown below:

FOR REGENERATIVE TRANSPONDERS

The two common schemes are:

- IF Remodulation scheme: In this technique the uplink RF spectrum is first translated down to low IF band , which is then modulated on to return RF.

- Demodulation- Remodulation scheme: The remodulation removes the uplink noise and interference from return modulation.

SATELLITE LAUNCH VEHICLES:

Satellites are launched into its orbit by the satellite launch vehicles. These satellite launch vehicles are basically multistage rockets. It is classified into two types:

- Expendable launch vehicle (ELV) eg: Ariane, Delta etc. These vehicles get destroyed in space and it also carries more than one satellite with it.

- Reusable launch vehicle (RLV). Also known as space transportation system (STV) eg: Space shuttle. In case of these satellites the vehicle will return back to the earth after leaving the satellite in space. Thus they can be reused again and again.

Components of Launch vehicle:

- Propulsion system.

- Auto piloting system

- Aerodynamic structure

- Interactive steering subsystem

DIFFERENCE OF COMMUNICATION SATELLITE FROM COMMUNICATION RELAY:

- For communication satellites the range is much higher than that of communication relay. Communication Satellite can cover up to several thousand kilometers.

- For communication satellite the uplink and the downlink frequency is the same. But for communication satellites the uplink and the downlink frequencies are different in order to avoid interference.

Different frequency bands used in satellite communication:

- Ultra high frequency band (UHF).

- C-Band.

- X-Band.

- Ku-Band

- Ka-Band.

Sunday, November 7, 2010

mechanical engineering devlopment

Development

Applications of mechanical engineering are found in the records of many ancient and medieval societies throughout the globe. In ancient Greece, the works of Archimedes (287 BC–212 BC) deeply influenced mechanics in the Western tradition and Heron of Alexandria (c. 10–70 AD) created the first steam engine.[2] In China, Zhang Heng (78–139 AD) improved a water clock and invented a seismometer, and Ma Jun (200–265 AD) invented a chariot with differential gears. The medieval Chinese horologist and engineer Su Song (1020–1101 AD) incorporated an escapement mechanism into his astronomical clock tower two centuries before any escapement can be found in clocks of medieval Europe, as well as the world's first known endless power-transmitting chain drive.[3]During the years from 7th to 15th century, the era called the Islamic Golden Age, there have been remarkable contributions from Muslim inventors in the field of mechanical technology. Al-Jazari, who was one of them, wrote his famous Book of Knowledge of Ingenious Mechanical Devices in 1206, and presented many mechanical designs. He is also considered to be the inventor of such mechanical devices which now form the very basic of mechanisms, such as the crankshaft and camshaft.[4]

Important breakthroughs in the foundations of mechanical engineering occurred in England during the 17th century when Sir Isaac Newton both formulated the three Newton's Laws of Motion and developed calculus. Newton was reluctant to publish his methods and laws for years, but he was finally persuaded to do so by his colleagues, such as Sir Edmund Halley, much to the benefit of all mankind.

During the early 19th century in England, Germany and Scotland, the development of machine tools led mechanical engineering to develop as a separate field within engineering, providing manufacturing machines and the engines to power them.[5] The first British professional society of mechanical engineers was formed in 1847, thirty years after civil engineers formed the first such professional society.[6] On the European continent, Johann Von Zimmermann (1820–1901) founded the first factory for grinding machines in Chemnitz (Germany) in 1848.

In the United States, the American Society of Mechanical Engineers (ASME) was formed in 1880, becoming the third such professional engineering society, after the American Society of Civil Engineers (1852) and the American Institute of Mining Engineers (1871).[7] The first schools in the United States to offer an engineering education were the United States Military Academy in 1817, an institution now known as Norwich University in 1819, and Rensselaer Polytechnic Institute in 1825. Education in mechanical engineering has historically been based on a strong foundation in mathematics and science.[8]

[edit] Education

Degrees in mechanical engineering are offered at universities worldwide. In Bangladesh, China, India, Nepal, North America, and Pakistan, mechanical engineering programs typically take four to five years of study and result in a Bachelor of Science (B.Sc), Bachelor of Technology (B.Tech), Bachelor of Engineering (B.Eng), or Bachelor of Applied Science (B.A.Sc) degree, in or with emphasis in mechanical engineering. In Spain, Portugal and most of South America, where neither BSc nor BTech programs have been adopted, the formal name for the degree is "Mechanical Engineer", and the course work is based on five or six years of training. In Italy the course work is based on five years of training; but in order to qualify as an Engineer you have to pass a state exam at the end of the course.In the United States, most undergraduate mechanical engineering programs are accredited by the Accreditation Board for Engineering and Technology (ABET) to ensure similar course requirements and standards among universities. The ABET web site lists 276 accredited mechanical engineering programs as of June 19, 2006.[9] Mechanical engineering programs in Canada are accredited by the Canadian Engineering Accreditation Board (CEAB),[10] and most other countries offering engineering degrees have similar accreditation societies.

Some mechanical engineers go on to pursue a postgraduate degree such as a Master of Engineering, Master of Technology, Master of Science, Master of Engineering Management (MEng.Mgt or MEM), a Doctor of Philosophy in engineering (EngD, PhD) or an engineer's degree. The master's and engineer's degrees may or may not include research. The Doctor of Philosophy includes a significant research component and is often viewed as the entry point to academia.[11] The Engineer's degree exists at a few institutions at an intermediate level between the master's degree and the doctorate.

[edit] Coursework

Standards set by each country's accreditation society are intended to provide uniformity in fundamental subject material, promote competence among graduating engineers, and to maintain confidence in the engineering profession as a whole. Engineering programs in the U.S., for example, are required by ABET to show that their students can "work professionally in both thermal and mechanical systems areas."[12] The specific courses required to graduate, however, may differ from program to program. Universities and Institutes of technology will often combine multiple subjects into a single class or split a subject into multiple classes, depending on the faculty available and the university's major area(s) of research.The fundamental subjects of mechanical engineering usually include:

- Statics and dynamics

- Strength of materials and solid mechanics

- Instrumentation and measurement

- Thermodynamics, heat transfer, energy conversion, and HVAC

- Fluid mechanics and fluid dynamics

- Mechanism design (including kinematics and dynamics)

- Manufacturing technology or processes

- Hydraulics and pneumatics

- Mathematics - in particular, calculus, differential equations, and linear algebra.

- Engineering design

- Mechatronics and control theory

- Material Engineering

- Drafting, CAD (including solid modeling), and CAM[13][14]

In addition to the core mechanical engineering curriculum, many mechanical engineering programs offer more specialized programs and classes, such as robotics, transport and logistics, cryogenics, fuel technology, automotive engineering, biomechanics, vibration, optics and others, if a separate department does not exist for these subjects.[15]

Most mechanical engineering programs also require varying amounts of research or community projects to gain practical problem-solving experience. In the United States it is common for mechanical engineering students to complete one or more internships while studying, though this is not typically mandated by the university. Cooperative education is another option.

[edit] License

Engineers may seek license by a state, provincial, or national government. The purpose of this process is to ensure that engineers possess the necessary technical knowledge, real-world experience, and knowledge of the local legal system to practice engineering at a professional level. Once certified, the engineer is given the title of Professional Engineer (in the United States, Canada, Japan, South Korea, Bangladesh and South Africa), Chartered Engineer (in the United Kingdom, Ireland, India and Zimbabwe), Chartered Professional Engineer (in Australia and New Zealand) or European Engineer (much of the European Union). Not all mechanical engineers choose to become licensed; those that do can be distinguished as Chartered or Professional Engineers by the post-nominal title P.E., P.Eng., or C.Eng., as in: Mike Thompson, P.Eng.In the U.S., to become a licensed Professional Engineer, an engineer must pass the comprehensive FE (Fundamentals of Engineering) exam, work a given number of years as an Engineering Intern (EI) or Engineer-in-Training (EIT), and finally pass the "Principles and Practice" or PE (Practicing Engineer or Professional Engineer) exams.

In the United States, the requirements and steps of this process are set forth by the National Council of Examiners for Engineering and Surveying (NCEES), a national non-profit representing all states. In the UK, current graduates require a BEng plus an appropriate masters degree or an integrated MEng degree, a minimum of 4 years post graduate on the job competency development, and a peer reviewed project report in the candidates specialty area in order to become chartered through the Institution of Mechanical Engineers.

In most modern countries, certain engineering tasks, such as the design of bridges, electric power plants, and chemical plants, must be approved by a Professional Engineer or a Chartered Engineer. "Only a licensed engineer, for instance, may prepare, sign, seal and submit engineering plans and drawings to a public authority for approval, or to seal engineering work for public and private clients."[16] This requirement can be written into state and provincial legislation, such as in the Canadian provinces, for example the Ontario or Quebec's Engineer Act.[17]

In other countries, such as Australia, no such legislation exists; however, practically all certifying bodies maintain a code of ethics independent of legislation that they expect all members to abide by or risk expulsion.[18]

[edit] Salaries and workforce statistics

The total number of engineers employed in the U.S. in 2009 was roughly 1.6 million. Of these, 239,000 were mechanical engineers (14.9%), the second largest discipline by size behind civil (278,000). The total number of mechanical engineering jobs in 2009 was projected to grow 6% over the next decade, with average starting salaries being $58,800 with a bachelor's degree.[19] The median annual income of mechanical engineers in the U.S. workforce was roughly $74,900. This number was highest when working for the government ($86,250), and lowest in education ($63,050).[20]In 2007, Canadian engineers made an average of CAD$29.83 per hour with 4% unemployed. The average for all occupations was $18.07 per hour with 7% unemployed. Twelve percent of these engineers were self-employed, and since 1997 the proportion of female engineers had risen to 6%.[21]

[edit] Modern tools

Many mechanical engineering companies, especially those in industrialized nations, have begun to incorporate computer-aided engineering (CAE) programs into their existing design and analysis processes, including 2D and 3D solid modeling computer-aided design (CAD). This method has many benefits, including easier and more exhaustive visualization of products, the ability to create virtual assemblies of parts, and the ease of use in designing mating interfaces and tolerances.Other CAE programs commonly used by mechanical engineers include product lifecycle management (PLM) tools and analysis tools used to perform complex simulations. Analysis tools may be used to predict product response to expected loads, including fatigue life and manufacturability. These tools include finite element analysis (FEA), computational fluid dynamics (CFD), and computer-aided manufacturing (CAM).

Using CAE programs, a mechanical design team can quickly and cheaply iterate the design process to develop a product that better meets cost, performance, and other constraints. No physical prototype need be created until the design nears completion, allowing hundreds or thousands of designs to be evaluated, instead of a relative few. In addition, CAE analysis programs can model complicated physical phenomena which cannot be solved by hand, such as viscoelasticity, complex contact between mating parts, or non-Newtonian flows

As mechanical engineering begins to merge with other disciplines, as seen in mechatronics, multidisciplinary design optimization (MDO) is being used with other CAE programs to automate and improve the iterative design process. MDO tools wrap around existing CAE processes, allowing product evaluation to continue even after the analyst goes home for the day. They also utilize sophisticated optimization algorithms to more intelligently explore possible designs, often finding better, innovative solutions to difficult multidisciplinary design problems.

[edit] Subdisciplines

The field of mechanical engineering can be thought of as a collection of many mechanical disciplines. Several of these subdisciplines which are typically taught at the undergraduate level are listed below, with a brief explanation and the most common application of each. Some of these subdisciplines are unique to mechanical engineering, while others are a combination of mechanical engineering and one or more other disciplines. Most work that a mechanical engineer does uses skills and techniques from several of these subdisciplines, as well as specialized subdisciplines. Specialized subdisciplines, as used in this article, are more likely to be the subject of graduate studies or on-the-job training than undergraduate research. Several specialized subdisciplines are discussed in this section.[edit] Mechanics

Main article: Mechanics

Mechanics is, in the most general sense, the study of forces and their effect upon matter. Typically, engineering mechanics is used to analyze and predict the acceleration and deformation (both elastic and plastic) of objects under known forces (also called loads) or stresses. Subdisciplines of mechanics include- Statics, the study of non-moving bodies under known loads, how forces affect static bodies

- Dynamics (or kinetics), the study of how forces affect moving bodies

- Mechanics of materials, the study of how different materials deform under various types of stress

- Fluid mechanics, the study of how fluids react to forces[22]

- Continuum mechanics, a method of applying mechanics that assumes that objects are continuous (rather than discrete)

[edit] Kinematics

Main article: Kinematics

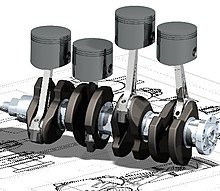

Kinematics is the study of the motion of bodies (objects) and systems (groups of objects), while ignoring the forces that cause the motion. The movement of a crane and the oscillations of a piston in an engine are both simple kinematic systems. The crane is a type of open kinematic chain, while the piston is part of a closed four-bar linkage.Mechanical engineers typically use kinematics in the design and analysis of mechanisms. Kinematics can be used to find the possible range of motion for a given mechanism, or, working in reverse, can be used to design a mechanism that has a desired range of motion.

[edit] Mechatronics and robotics

Training FMS with learning robot SCORBOT-ER 4u, workbench CNC Mill and CNC Lathe

Main articles: Mechatronics and Robotics

Mechatronics is an interdisciplinary branch of mechanical engineering, electrical engineering and software engineering that is concerned with integrating electrical and mechanical engineering to create hybrid systems. In this way, machines can be automated through the use of electric motors, servo-mechanisms, and other electrical systems in conjunction with special software. A common example of a mechatronics system is a CD-ROM drive. Mechanical systems open and close the drive, spin the CD and move the laser, while an optical system reads the data on the CD and converts it to bits. Integrated software controls the process and communicates the contents of the CD to the computer.Robotics is the application of mechatronics to create robots, which are often used in industry to perform tasks that are dangerous, unpleasant, or repetitive. These robots may be of any shape and size, but all are preprogrammed and interact physically with the world. To create a robot, an engineer typically employs kinematics (to determine the robot's range of motion) and mechanics (to determine the stresses within the robot).

Robots are used extensively in industrial engineering. They allow businesses to save money on labor, perform tasks that are either too dangerous or too precise for humans to perform them economically, and to insure better quality. Many companies employ assembly lines of robots, and some factories are so robotized that they can run by themselves. Outside the factory, robots have been employed in bomb disposal, space exploration, and many other fields. Robots are also sold for various residential applications.

[edit] Structural analysis

Main articles: Structural analysis and Failure analysis

Structural analysis is the branch of mechanical engineering (and also civil engineering) devoted to examining why and how objects fail and to fix the objects and their performance. Structural failures occur in two general modes: static failure, and fatigue failure. Static structural failure occurs when, upon being loaded (having a force applied) the object being analyzed either breaks or is deformed plastically, depending on the criterion for failure. Fatigue failure occurs when an object fails after a number of repeated loading and unloading cycles. Fatigue failure occurs because of imperfections in the object: a microscopic crack on the surface of the object, for instance, will grow slightly with each cycle (propagation) until the crack is large enough to cause ultimate failure.Failure is not simply defined as when a part breaks, however; it is defined as when a part does not operate as intended. Some systems, such as the perforated top sections of some plastic bags, are designed to break. If these systems do not break, failure analysis might be employed to determine the cause.

Structural analysis is often used by mechanical engineers after a failure has occurred, or when designing to prevent failure. Engineers often use online documents and books such as those published by ASM[23] to aid them in determining the type of failure and possible causes.

Structural analysis may be used in the office when designing parts, in the field to analyze failed parts, or in laboratories where parts might undergo controlled failure tests.

[edit] Thermodynamics and thermo-science

Main article: Thermodynamics

Thermodynamics is an applied science used in several branches of engineering, including mechanical and chemical engineering. At its simplest, thermodynamics is the study of energy, its use and transformation through a system. Typically, engineering thermodynamics is concerned with changing energy from one form to another. As an example, automotive engines convert chemical energy (enthalpy) from the fuel into heat, and then into mechanical work that eventually turns the wheels.Thermodynamics principles are used by mechanical engineers in the fields of heat transfer, thermofluids, and energy conversion. Mechanical engineers use thermo-science to design engines and power plants, heating, ventilation, and air-conditioning (HVAC) systems, heat exchangers, heat sinks, radiators, refrigeration, insulation, and others.

[edit] Drafting

A CAD model of a mechanical double seal

Main articles: Technical drawing and CNC

Drafting or technical drawing is the means by which mechanical engineers create instructions for manufacturing parts. A technical drawing can be a computer model or hand-drawn schematic showing all the dimensions necessary to manufacture a part, as well as assembly notes, a list of required materials, and other pertinent information. A U.S. mechanical engineer or skilled worker who creates technical drawings may be referred to as a drafter or draftsman. Drafting has historically been a two-dimensional process, but computer-aided design (CAD) programs now allow the designer to create in three dimensions.Instructions for manufacturing a part must be fed to the necessary machinery, either manually, through programmed instructions, or through the use of a computer-aided manufacturing (CAM) or combined CAD/CAM program. Optionally, an engineer may also manually manufacture a part using the technical drawings, but this is becoming an increasing rarity, with the advent of computer numerically controlled (CNC) manufacturing. Engineers primarily manually manufacture parts in the areas of applied spray coatings, finishes, and other processes that cannot economically or practically be done by a machine.

Drafting is used in nearly every subdiscipline of mechanical engineering, and by many other branches of engineering and architecture. Three-dimensional models created using CAD software are also commonly used in finite element analysis (FEA) and computational fluid dynamics (CFD).

[edit] Frontiers of research

Mechanical engineers are constantly pushing the boundaries of what is physically possible in order to produce safer, cheaper, and more efficient machines and mechanical systems. Some technologies at the cutting edge of mechanical engineering are listed below (see also exploratory engineering).[edit] Micro electro-mechanical systems (MEMS)

Micron-scale mechanical components such as springs, gears, fluidic and heat transfer devices are fabricated from a variety of substrate materials such as silicon, glass and polymers like SU8. Examples of MEMS components will be the accelerometers that are used as car airbag sensors, gyroscopes for precise positioning and microfluidic devices used in biomedical applications.[edit] Friction stir welding (FSW)

Main article: Friction stir welding

Friction stir welding, a new type of welding, was discovered in 1991 by The Welding Institute (TWI). This innovative steady state (non-fusion) welding technique joins materials previously un-weldable, including several aluminum alloys. It may play an important role in the future construction of airplanes, potentially replacing rivets. Current uses of this technology to date include welding the seams of the aluminum main Space Shuttle external tank, Orion Crew Vehicle test article, Boeing Delta II and Delta IV Expendable Launch Vehicles and the SpaceX Falcon 1 rocket, armor plating for amphibious assault ships, and welding the wings and fuselage panels of the new Eclipse 500 aircraft from Eclipse Aviation among an increasingly growing pool of uses.[24][25][26][27][dead link][edit] Composites

Main article: Composite material

Composites or composite materials are a combination of materials which provide different physical characteristics than either material separately. Composite material research within mechanical engineering typically focuses on designing (and, subsequently, finding applications for) stronger or more rigid materials while attempting to reduce weight, susceptibility to corrosion, and other undesirable factors. Carbon fiber reinforced composites, for instance, have been used in such diverse applications as spacecraft and fishing rods.[edit] Mechatronics

Main article: Mechatronics

Mechatronics is the synergistic combination of mechanical engineering, Electronic Engineering, and software engineering. The purpose of this interdisciplinary engineering field is the study of automata from an engineering perspective and serves the purposes of controlling advanced hybrid systems.[edit] Nanotechnology

Main article: Nanotechnology

At the smallest scales, mechanical engineering becomes nanotechnology —one speculative goal of which is to create a molecular assembler to build molecules and materials via mechanosynthesis. For now that goal remains within exploratory engineering.[edit] Finite element analysis

Main article: Finite element analysis

This field is not new, as the basis of Finite Element Analysis (FEA) or Finite Element Method (FEM) dates back to 1941. But evolution of computers has made FEM a viable option for analysis of structural problems. Many commercial codes such as ANSYS, Nastran and ABAQUS are widely used in industry for research and design of components.Other techniques such as finite difference method (FDM) and finite-volume method (FVM) are employed to solve problems relating heat and mass transfer, fluid flows, fluid surface interaction etc.

[edit] Related fields

Manufacturing engineering and Aerospace Engineering are sometimes grouped with mechanical engineering. A bachelor's degree in these areas will typically have a difference of a few specialized classes.[edit] See also

| At Wikiversity you can learn more and teach others about Mechanical engineering at: |

[edit] Associations

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE)

- American Society of Mechanical Engineers (ASME)

- Pi Tau Sigma (Mechanical Engineering Honor Society)

- Society of Automotive Engineers

- Society of Women Engineers

- Institution of Mechanical Engineers (IMechE) (British)

- Chartered Institution of Building Services Engineers (CIBSE) (British)

- Pakistan Engineering Council (PEC)

- UCTEA-CMO (Chamber of Mechanical Engineers) (Turkish)

- Philippine Society of Mechanical Engineers (PSME)

[edit] Wikibooks

[edit] Notes and references

- ^ engineering "mechanical engineering. (n.d.)". The American Heritage Dictionary of the English Language, Fourth Edition. Retrieved: May 08, 2010.

- ^ "Heron of Alexandria". Encyclopædia Britannica 2010 - Encyclopædia Britannica Online. Accessed: 09 May 2010.

- ^ Needham, Joseph (1986). Science and Civilization in China: Volume 4. Taipei: Caves Books, Ltd.

- ^ Al-Jazarí. The Book of Knowledge of Ingenious Mechanical Devices: Kitáb fí ma'rifat al-hiyal al-handasiyya. Springer, 1973. ISBN 9027703299.

- ^ Engineering - Encyclopedia Brittanica, accessed 06 May 2008

- ^ R. A. Buchanan. The Economic History Review, New Series, Vol. 38, No. 1 (Feb., 1985), pp. 42–60.

- ^ ASME history, accessed 06 May 2008.

- ^ The Columbia Encyclopedia, Sixth Edition. 2001-07, engineering, accessed 06 May 2008

- ^ ABET searchable database of accredited engineering programs, Accessed June 19, 2006.

- ^ Accredited engineering programs in Canada by the Canadian Council of Professional Engineers, Accessed April 18, 2007.

- ^ Types of post-graduate degrees offered at MIT - Accessed 19 June 2006.

- ^ 2008-2009 ABET Criteria, p. 15.

- ^ University of Tulsa Required ME Courses - http://www.me.utulsa.edu/Undergraduate.html - Accessed 19 June 2006

- ^ Harvard Mechanical Engineering Page - Accessed 19 June 2006

- ^ Mechanical Engineering courses, MIT. Accessed 14 June 2008.

- ^ "Why Get Licensed?". National Society of Professional Engineers. http://www.nspe.org/Licensure/WhyGetLicensed/index.html. Retrieved May 6, 2008.

- ^ "Engineers Act". Quebec Statutes and Regulations (CanLII). http://www.canlii.org/qc/laws/sta/i-9/20050616/whole.html. Retrieved July 24, 2005.

- ^ "Codes of Ethics and Conduct". Online Ethics Center. Archived from the original on June 19, 2005. http://web.archive.org/web/20050619081942/http://onlineethics.org/codes/. Retrieved July 24, 2005.

- ^ 2010-11 Edition, Engineers - Bureau of Labor Statistics, U.S. Department of Labor, Occupational Outlook Handbook, Accessed: 9 May 2010.

- ^ Document National Sector NAICS Industry-Specific estimates (xls) Accessed: 9 May 2010.

- ^ Mechanical Engineers - Jobfutures.ca, Accessed: June 30, 2007.

- ^ Note: fluid mechanics can be further split into fluid statics and fluid dynamics, and is itself a subdiscipline of continuum mechanics. The application of fluid mechanics in engineering is called hydraulics and pneumatics.

- ^ ASM International's site containing more than 20,000 searchable documents, including articles from the ASM Handbook series and Advanced Materials & Processes

- ^ Advances in Friction Stir Welding for Aerospace Applications

- ^ PROPOSAL NUMBER: 08-1 A1.02-9322 - NASA 2008 SBIR

- ^ Nova-Tech LLC

- ^ http://www.comsol.com/industry/htmlpaper/colegrove_stir_welding

[edit] Further reading

- Burstall, Aubrey F. (1965). A History of Mechanical Engineering. The MIT Press. ISBN 0-262-52001-X.

[edit] External links

| Wikibooks has a book on the topic of |

| Wikibooks has a book on the topic of |

- Kinematic Models for Design Digital Library (KMODDL) - Movies and photos of hundreds of working mechanical-systems models at Cornell University. Also includes an e-book library of classic texts on mechanical design and engineering.

Subscribe to:

Posts (Atom)